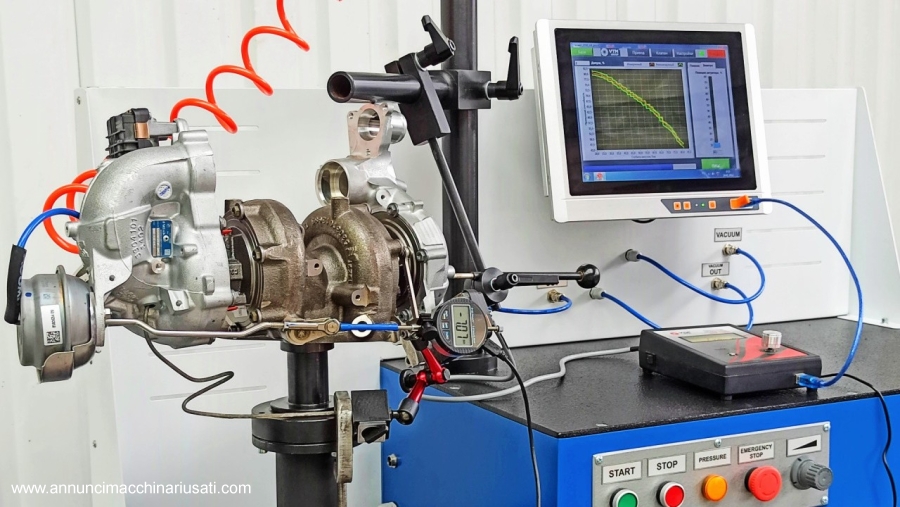

The bench is used to adjust the variable geometry mechanism of the turbocharger after repair. It can adjust turbocharger geometry without rotating the shaft, suitable for vacuum, air, and electronically controlled turbochargers.

A unique feature of the GEOMET 2000 is its ability to check the N75 valve, crucial for controlling the turbocharger in the vehicle. It also allows assessing the condition of the actuator spring for better diagnosis.

It can tune different types of variable geometry turbochargers:

- Variable-Nozzle Turbine (VNT)

- Variable-Area Turbine Nozzle (VATN)

- Variable-Turbine Geometry (VTG)

- Variable-Geometry Turbo (VGT)

- Variable-Vane Turbine (VVT)

- Turbine airflow rate test - Pneumatically or electronically controlled turbine nozzle train settings based on master data.

- Vacuum-valve stroke test - Measure piston stroke vs. vacuum (or pressure) in the valve in static mode.

- Checking actuation and smooth stroke of guide vanes - Determine how much the guide vanes open when the vacuum in the valve decreases, and check the resiliency of the valve spring.

- Verification of N75 valve operation - Check the valve serviceability and characteristics at a given duty cycle for turbines with vacuum valve.

- The test bench includes specially developed Turbo Test software, which generates diagrams and allows printing reports on the tuning procedure.

- The base supports 6200 turbines, with the possibility of replenishment through USB or independent tuning of turbines from the manufacturer.