Description

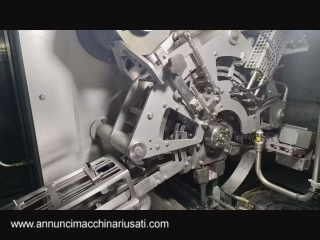

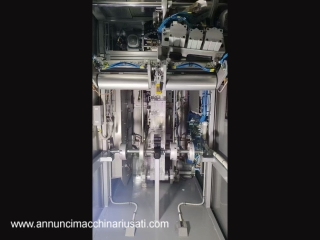

Description Used TETRA PAK A3 Flex 7,500 bph Filling Machine The used TETRA PAK A3 Flex 7,500 bph filling machine offers advanced performance for bottling applications in the food industry. Operators commonly use this machine for the production of UHT milk and fruit drinks. The system delivers high productivity, handles various packaging formats, and maintains long-term reliability. Production Capacity and Format Handling The TETRA PAK A3 Flex processes up to 7,500 containers per hour. As a result, it supports production environments that require high efficiency across multiple shifts. Additionally, the used TETRA PAK A3 Flex 7,500 bph filling machine handles both the Prisma and Slim formats, which manufacturers often choose for aseptic packaging. As a result, the machine allows operators to quickly change formats without modifying key components. This flexibility reduces downtime and increases productivity. Automatic Filling System The automatic filling system ensures precise dosing during operation. Specifically, the machine processes low- and medium-viscosity liquids such as milk, juices, and functional beverages, including those with pulp. Furthermore, engineers designed its modular architecture to allow for rapid product changeovers while maintaining hygienic conditions. The used TETRA PAK A3 Flex 7500 bph filler forms and seals containers using a process that protects their microbiological integrity. As such, it ensures that the final product meets food safety standards. Production monitoring and traceability: The integrated production log, or work diary, tracks all operational data, including cycle times, error codes, and outages. Supervisors therefore use this information to monitor each batch and respond to deviations in real time. Furthermore, the system ensures full traceability and complies with modern food safety regulations. Specifically, the used TETRA PAK A3 Flex 7500 bph filler provides digital recording that supports audits and process validation. This feature, in turn, facilitates compliance with internal and external quality assurance protocols. Maintenance and Technical Accessibility: Technicians can easily access key components thanks to the machine's modular layout. Likewise, the system separates functional units such as filling, forming, and sealing, allowing targeted intervention without shutting down the entire line. As a result, the design reduces maintenance time and operating costs. Operators can also connect the used TETRA PAK A3 Flex 7500 bph filler to predictive maintenance systems based on Industry 4.0 standards. Thus, the machine enables proactive asset management and long-term equipment reliability. Plant Compatibility and Regulatory Compliance: System integrators can install this machine into existing production lines with minimal adaptation. In many cases, the machine includes interfaces compliant with standard industrial automation protocols. As a result, both electrical and pneumatic connections meet EU requirements, simplifying installation in regulated environments. Furthermore, the used TETRA PAK A3 Flex 7500 bph filling machine complies with food safety, hygiene, and occupational safety regulations. Therefore, it is suitable for operations certified according to the HACCP, IFS, and BRC frameworks. Technical conclusion In conclusion, the used TETRA PAK A3 Flex 7500 bph filling machine offers a reliable, high-performance solution for aseptic filling operations. Most importantly, the system supports rapid format changeovers, enables real-time monitoring, and integrates seamlessly into existing facilities. Above all, manufacturers requiring continuous production, traceability, and minimal downtime will greatly benefit from this machine's capabilities. Ultimately, the used TETRA PAK A3 Flex 7500 bph filling machine helps optimize operational efficiency while maintaining strict compliance with industry standards.