Description

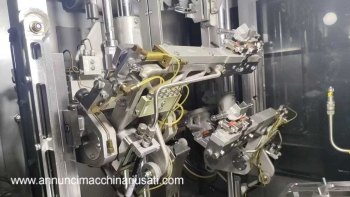

Used Tetra Pak A3 Compact Flex 300V Aseptic Carton Filling Machine + TSA21 Straw Applicator, Year 2007 – Overview This used Tetra Pak A3 Compact Flex 300V aseptic filling machine is designed for highly efficient packaging of liquid foods in the 200 ml Slim format. With a capacity of up to 9,000 units per hour, it offers reliable performance for beverage production and industrial packaging operations seeking quality-proven pre-owned equipment. Manufactured by Tetra Pak, a leading name in packaging machinery, this filler supports aseptic processing for sensitive products such as milk and juice, making it a solid choice for modern used bottling and carton packaging applications. Designed for advanced aseptic filling performance, the A3 Compact Flex 300V combines process control, operational safety, and consistent production. The machine has been maintained in line with contemporary standards, ensuring reliable uptime, product integrity and efficient transitions in demanding beverage production environments. Technical Specifications and Performance Data Manufacturer: Tetra Pak Model/Version: A3 Compact Flex 300V Year of Manufacture: 2016 Production Rate: Up to 9,000 units/hour Primary Format: 200ml Slim Filling Technology: Aseptic Carton Filling Recorded Opening Hours: 10,538 h (approx.) Straw Applicator System TSA21 Product Examples: Milk, Juice Container Type: Carton Packages Advanced Automation and Control Systems The system features an integrated control panel and HMI for process monitoring, recipe management and production diagnostics. Automated sequences support aseptic start-up, steady-state operation and controlled shutdown. The platform incorporates safety and security interlocks to protect operators while allowing quick access for routine cleaning and service. Tetra Pak engineering ensures coordinated control of the forming, filling, and sealing phases for stable, repeatable performance. Production Line Integration Capability: This filler integrates seamlessly into complete beverage production lines and industrial packaging. It is suitable for upstream UHT/ESL processing and for case packing, conveyor belting, and palletizing. The 200ml Slim format aligns with standard secondary packaging solutions, supporting efficient logistics. The machine can operate as a central element in a pre-owned bottling line configured for aseptic cartons. Machine Condition and Maintenance History: Condition reported as perfect, with maintenance aligning the unit with modern standards for process control, performance, and operational safety. The machine is ready for use and suitable for immediate installation after installation and commissioning within the buyer's facility. Operational Performance and Versatility Optimized for aseptic filling of dairy beverages and juices, this A3 Compact Flex 300V maintains product quality under controlled sterile conditions. Consistent seal quality, accurate fill control, and stable carton handling result in reduced waste and high line efficiency. The platform is well-regarded for its reliability in high-demand beverage production. Installation Requirements and Site Preparation: Installation requires adequate space for carton infeed, machine access, and downstream transportation. Typical utilities include electricity, compressed air, and utilities necessary for operation and aseptic cleaning. Proper environmental control and a hygienic layout support aseptic performance and maintenance access. Safety Standards and Compliance Certification: Designed with full perimeter protection, safety interlocks, and emergency stop systems to protect operators and maintain aseptic integrity. Hygienic construction and cleanable surfaces support stringent food safety practices required in dairy and juice packaging environments.