Description

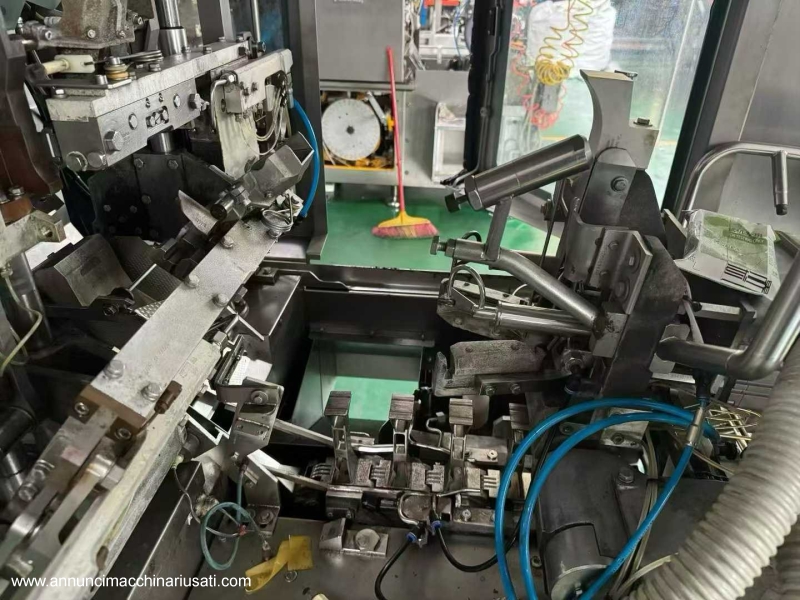

Technical Specifications and Performance Data This used complete bottling line is configured for aseptic carton packs in the Tetra Pak Prisma 0.33L format. Designed around proven Tetra Pak components, it offers a compact and reliable solution for producing high-quality industrial packaging and beverages. The line configuration integrates filling, capping, and packaging functions with smooth container handling for stable operation and consistent output. Production Rate: 7500 pcs/hr Format: 0.33L Prisma (square) Container Type: Carton (Tetra Pak Prisma) Line Configuration: TBA19 (Filler) + TCA45 (Capper) + TCBP70 (Packer) Filler Model: TBD 19 Capper Model: TCA45 Packer Model: TCBP70 Operating Mode: Aseptic Packaging Line for Shelf-Life Beverage Manufacturer: Tetra Pak Advanced Automation and Control Systems The line benefits from Tetra Pak engineering with integrated automation that supports stable aseptic operation. Centralized controls coordinate filling, capper, and packer modules for synchronized speed, accurate timing, and reduced downtime. Recipe-based settings enable consistent configuration for the 0.33L Prisma format, and easily accessible HMI interfaces facilitate monitoring, diagnostics, and quick adjustments during production. Production Line Integration Capability Designed for seamless integration into a complete production environment, this used bottling line supports upstream and downstream connections such as feed management, carton supply, and end-of-line palletizing. The Prisma 0.33L format is standard in the configuration, ensuring reliable format management and efficient changeovers within the same format family. Logical conveyor and module interfaces help maintain continuous flow and balanced line performance in pre-owned industrial packaging applications. Machine Condition and Maintenance History This pre-owned line is offered in operating condition and ready for use, with original model identification on the equipment. Tetra Pak's functional design supports routine maintenance, with wear parts and critical aseptic parts accessible for inspection and replacement following standard preventative maintenance practices. The line is suitable for facilities looking to expand or standardize aseptic beverage production without significant commissioning delays. Operational Performance and Versatility Optimized for aseptic processing, the system provides controlled management from filling to capping and packaging. The TBA19 ensures accurate filling under aseptic conditions; the TCA45 applies compatible closures for Prisma cartons; and the TCBP70 organizes secondary packaging for efficient logistics. The result is a robust solution for industrial packaging, where product protection, shelf life, and consistent presentation are essential. Installation Requirements and Site Preparation: The line is intended for installation in a hygienic production area with controlled environmental conditions suitable for aseptic operations. Site preparation should include adequate space for the filling modules, cappers, and packers with service access, utility routing, and safe walkways for operators. Utilities typically required for aseptic carton packaging include electricity, compressed air, and process services appropriate for aseptic operation. Proper layout planning ensures smooth material flow and efficient maintenance access. Safety standards and compliance certification. Designed with complete machine protection and operator safety features, the line includes interlocked access and emergency stop systems to support safe operation. Hygienic design principles, stainless steel contact parts where applicable, and enclosed processing paths meet the stringent expectations of the food and beverage industry. Tetra Pak engineering helps ensure that safety, hygiene, and production integrity are maintained throughout all stages of filling, capping, and packaging