Description

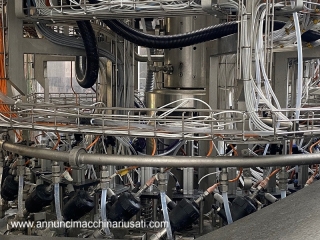

The used KHS aseptic isobaric bottling line for PET (27,000 bph) provides a high-tech solution for bottling beverages in PET bottles. Furthermore, this line handles bottle sizes ranging from 0.33 liters to 2.5 liters and can effectively adapt to various production needs. Therefore, manufacturers seeking flexibility benefit greatly from this line. Products and Production Capacity The used KHS aseptic isobaric bottling line for PET (27,000 bph) processes soft drinks and fruit juices, offering production capacities that vary based on the type of beverage and bottle format. As a result, manufacturers can optimize production to meet product demand. Carbonated beverage production capacity of the used KHS aseptic isobaric bottling line for PET (27,000 bph) 0.50-liter bottles: this line produces 22,000 bottles/hour, ensuring efficient production. 1-liter bottles: The line can handle 18,000 bottles/hour, making it suitable for medium-sized production. 1.5-liter bottles: It handles 16,000 bottles/hour, allowing for flexible production planning. 2-liter bottles: The line processes 15,000 bottles/hour, efficiently handling larger formats. Still beverage production capacity: 0.33-liter, 0.50-liter, 0.75-liter, and 1-liter bottles: This line produces 27,000 bottles/hour, ensuring high productivity for smaller formats. 1.5-liter bottles: It processes 19,000 bottles/hour, improving production flexibility. 2-liter bottles: The line handles 15,000 bottles/hour, accommodating multiple product lines. Operational History and Filling Technology The used KHS 27,000 bph PET aseptic isobaric bottling line has operated for approximately 80,000 hours. Operators completed a complete upgrade in 2019 and a major overhaul at 76,000 hours by the end of 2021. As a result, the equipment maintains excellent performance standards. It uses isobaric filling technology, which optimizes pressure control during the filling process. This technology efficiently handles carbonated beverages and ensures product quality and safety. Composition of the Used KHS 27,000 bph PET aseptic isobaric bottling line The line includes the following equipment, all from the KHS brand, ensuring consistent integration and performance: Cap sterilizer: KHS SCS8 and SCT4 (2006) The KHS SCS8 and SCT4 cap sterilizer systems completely sterilize caps before sealing bottles. They preserve the internal sterility of the product, using steam and chemical solutions to eliminate microorganisms. Furthermore, the SCS8 model processes caps to meet stringent hygiene standards, while the SCT4 model efficiently handles large volumes of caps, ensuring a constant supply. Filler: KHS Alfill (2006) The KHS Alfill filler ensures sterile filling of bottles under controlled conditions. Furthermore, it supports both isobaric and aseptic filling for sensitive products such as fruit juices, tea, dairy products and carbonated drinks. This contactless filling system prevents contamination, while integrated pressure and temperature controls allow for precise product dosing. Thanks to sealed chambers and HEPA filters, it minimizes the risk of contamination and maintains efficiency. Inspector: KHS METEC FMS BV (2006) (For cap and filling control) The KHS METEC FMS BV inspection system ensures that caps and fill levels meet the required standards. Optical and laser sensors verify correct cap application and correct fill levels. Furthermore, any anomalies trigger automatic rejection without interrupting production, ensuring that only compliant products are processed. Used Aseptic Bottling Line CIP System: KHS Innopro (2006) The KHS Innopro Clean-in-Place (CIP) system automates the internal cleaning and sterilization of equipment. It customizes cleaning cycles using chemical solutions and sterile water. Thanks to integrated sensors, it continuously monitors detergent concentration and temperature, ensuring thorough cleaning, reducing downtime and maintaining optimal sterility conditions. Data Acquisition System: KHS AIS MIDI The KHS AIS MIDI data acquisition system monitors the bottling line in real time. It collects data on production speed, fill levels, sterility, and energy consumption. Additionally, operators receive real-time alerts for rapid intervention, ensuring efficiency and product safety. Its traceability features support compliance with food safety standards. Labeler: KHS Innoket-SE 60/120 2 RF 1HS PT The KHS Innoket-SE labeler applies wrap-around labels hygienically. It avoids compromising the sterility of sealed bottles. With two rotating stations, it handles high production volumes, applying labels precisely using sensors for accurate positioning. Additionally, its hygienic design ensures compatibility with aseptic environments. Inspector: KHS METEC-ETK (for label control) The KHS METEC-ETK inspection system verifies label quality, detecting creases, misalignments, and illegible prints. Additionally, high-resolution cameras and analysis software automatically reject non-compliant products, maintaining high visual and regulatory standards. Conveyor: KHS Innoline The KHS Innoline conveyor system smoothly transports bottles through the line, minimizing contact and contamination. Stainless steel components ensure hygienic operations, while sensors automatically adjust speed to prevent bottlenecks or product buildup. Shrink Wrapper: KHS TSP 050 V TPFO The KHS TSP 050 V TPFO shrink wrapper protects bottles during transport. Precise temperature control ensures the shrink film adheres tightly without distorting the bottles. This creates a secure package ready for distribution. Handle Applicator for Used Aseptic Bottling Line: KHS CSM 050-2 The KHS CSM 050-2 handle applicator attaches carrying handles to bottle packages without compromising sterility. Its automated design ensures precise application and integrates seamlessly into the production line, thus improving overall efficiency. Tray Packer for Used Aseptic Bottling Line: KHS TP 035B The KHS TP 035B tray packer safely organizes bottle packages for transport. Automatically positions and secures trays, ensuring packages remain stable and protected during storage and shipping. Operational synergy and quality control of the used KHS aseptic isobaric bottling line for PET 27,000 bph. Each machine within the line integrates seamlessly, reducing downtime and optimizing production. Furthermore, the control and data acquisition system monitors all production phases, allowing for rapid intervention in the event of anomalies. METEC inspection systems continuously check caps, bottles, and labels, ensuring only compliant products are processed. The automated CIP system maintains hygienic conditions without production interruptions, improving overall reliability. The used KHS aseptic isobaric bottling line for PET 27,000 bph offers a highly advanced, flexible, and efficient bottling solution for beverage manufacturers. Its ability to handle multiple formats and maintain high quality standards makes it a valuable asset in modern bottling plants.