Description

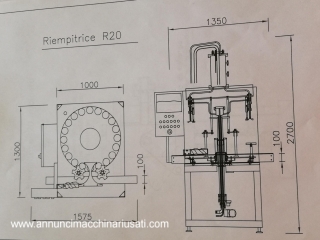

New Hot Fill Filler up to 4500 L/h Introduction: Filling machines are a perfectly reliable option for bottling operations. With a nominal speed of approximately 4500 liters per hour, this system offers consistent performance and unparalleled versatility for a wide range of products. Machine description: The new Hot Fill filler up to 4500 L/h consists of a filler with 20 taps, each equipped with a 22 mm diameter straw. Furthermore, all components in direct contact with the liquid are meticulously crafted from 316 stainless steel, ensuring maximum hygiene and corrosion resistance. A dedicated pump efficiently conveys the liquid to the filler, while the insertion of dummy bottles facilitates thorough cleaning of the taps. The height-adjustable bell, with an electrical drive, allows for the adaptation to accommodate containers of various sizes. Furthermore, the machine's rotation speed is variable via an inverter, thus allowing for precise control of the filling process. Precisely guided mechanical bottle-lifting pistons ensure accurate and uniform filling. Constructed entirely of stainless steel, the monoblock is equipped with safety guards surrounding its perimeter, thus safeguarding operators during operation. Furthermore, the bottle inlet, ingeniously positioned from the left, streamlines the workflow. Currently configured for glass bottles, the machine is also adaptable for rigid PET containers. Equipped with a mechanical valve dedicated exclusively to filling, the system ensures meticulous and reliable process control. Technical specifications of the equipment: Year of construction: 2024 Rated speed: approximately 4500 liters per hour Materials: 316 stainless steel Weight: 900 kilograms Voltage: 380 volts three-phase plus neutral, 50 Hz Applications and compatibility: The new Hot Fill 20 R. filler, up to 4500 L/h, suitable for containers with twist-off caps, features low-pressure filling ideal for juices, liqueurs, or oils. Currently configured for wide-mouth jars, a perfect fit is possible for bottles. Its ability to accommodate two different jar sizes is noteworthy. Conclusion: In summary, the new DAL TOSO filler, operating at up to 4500 L/h, represents a reliable and versatile solution for bottling operations. With consistent performance, hygienic design, and operational flexibility, this system represents an exceptional way to optimize production and ensure the quality of the final product.