Descrizione

Camera di preparazione del latte UHT usata Tetra Pak 6600 L/h

Panoramica tecnica del sistema

La sala di preparazione del latte UHT usato Tetra Pak 6600 L/h offre una soluzione completa per la preparazione asettica di latte UHT, yogurt da bere, succhi di frutta e bevande aromatizzate. Attualmente in stoccaggio e pronto per la reinstallazione, il sistema offre un’elevata efficienza termica e microbiologica. Inoltre, il suo design modulare gli consente di funzionare a 2640 L/h, 3850 L/h e fino a 6600 L/h in configurazione completa. Pertanto, si adatta bene alle diverse esigenze di produzione.

Sezione Omogeneizzazione

Al centro della sala di preparazione del latte UHT usato Tetra Pak 6600 L/h si trova un omogeneizzatore Tetra Pak, modello Tetra Alex, che garantisce un “efficace riduzione delle dimensioni dei globuli di grasso e una consistenza uniforme del prodotto. Di conseguenza, stabilizza emulsioni complesse come il latte aromatizzato o lo yogurt da bere e previene la separazione di fase durante lo stoccaggio. È importante sottolineare che questo omogeneizzatore non è asettico e opera a monte del processo di sterilizzazione UHT, eliminando qualsiasi carica microbica introdotta durante l” omogeneizzazione. Inoltre, l “omogeneizzatore supporta elevate pressioni di esercizio e semplifica la manutenzione. Inoltre, la struttura robusta garantisce un” affidabilità a lungo termine.

Sistema di disaerazione integrato

Il sistema include un degasatore Tetra Pak (2005) dotato di pompa ausiliaria e serbatoio. In particolare, questo componente rimuove l’ossigeno disciolto e i gas indesiderati dal prodotto prima del trattamento termico. Di conseguenza, migliora la stabilità del prodotto e riduce l’ossidazione. Inoltre, la configurazione verticale garantisce un’efficiente separazione dei gas. Nel frattempo, il design riduce al minimo la perdita di prodotto e garantisce un flusso continuo verso la fase successiva.

Modulo UHT tubolare ad alte prestazioni

La sterilizzazione termica avviene attraverso uno scambiatore di calore UHT tubolare, prodotto da Tetra Pak e modello Tetra Therm Aseptic. In particolare, questo componente sterilizza i prodotti tramite scambio termico indiretto preservandone le proprietà organolettiche. È importante sottolineare che il modulo include una bobina di tenuta per mantenere la temperatura in un intervallo di tempo definito. Pertanto, è conforme alle normative sulla sicurezza alimentare e garantisce la sicurezza microbiologica. Allo stesso modo, il suo design modulare consente una facile integrazione nelle linee esistenti.

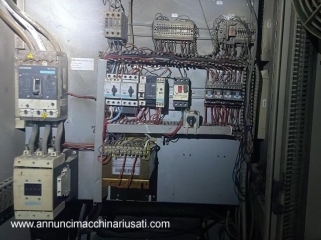

Controllo elettronico e automazione

La linea è dotata di un quadro elettrico di controllo, di un PLC Siemens e di pannelli operatore per la gestione precisa di ogni fase. In particolare, include schemi elettrici dettagliati, valvole pneumatiche Festo e inverter Danfoss per controllare dinamicamente pompe e scambiatori di calore. In questo modo, l “automazione consente un” elaborazione continua. Inoltre, ottimizza i cicli CIP, riduce i tempi di inattività e migliora la tracciabilità. Soprattutto, garantisce prestazioni affidabili in diverse condizioni operative.

Conclusione

In sintesi, la sala di preparazione del latte UHT usato Tetra Pak 6600 L/h offre un sistema completo e ad alta efficienza per la preparazione di latte e bevande UHT. Grazie ai suoi componenti di alto livello e al design scalabile, questa linea rappresenta la scelta ideale per i produttori di prodotti lattiero-caseari. Che l’obiettivo sia l’affidabilità, l’igiene o l’adattabilità, questa soluzione soddisfa i rigorosi standard del settore. Infine, il sistema rimane in deposito ed è disponibile per l’installazione immediata.