Newsletter

Always Stay Updated

Agency

Useful Links

Used Machinery Ads

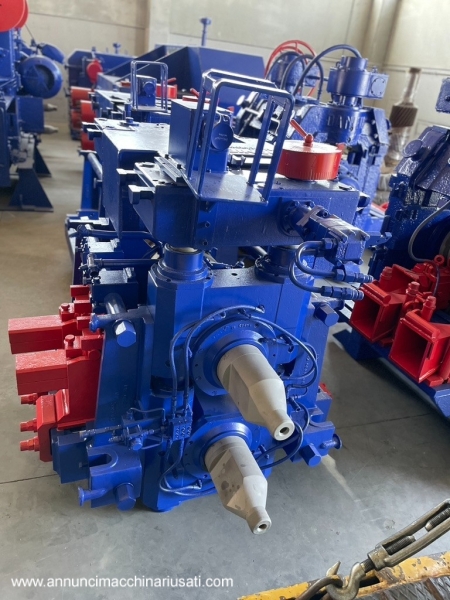

Explore the vast selection of quality machinery on AnnunciMacchinariUsati.com. From industrial equipment to specialty vehicles, find the best deals in the world of used machinery. Reliability, transparency, and wide variety: all just a click away. Find out more today!