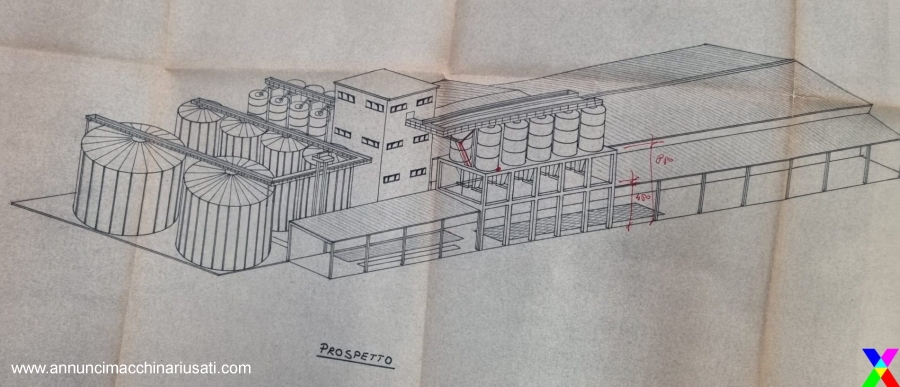

Description

15 TON/HOUR FEED MILL: FLOURS, BULK OR BAGGED CUBES. The machinery, equipment, and the entire vertical production and processing plant were built in the 1990s by a leading company in the relevant sector and is still in active operation. In fact, the feed mill has never been operational due to bureaucratic issues; for this reason, it can be considered as new. The process is designed for the production of grains for livestock, particularly supplementary feed for pigs, cattle, sheep, poultry, etc., and produces products in the form of flours, cubes, and crushed products, both loose and packaged. The plant's specific design and production cycle include ten self-sufficient processing phases, encompassing the entire process up to packaging and palletizing. In short, the production process begins in the shed-patio where the raw materials are received (weighed and unloaded). The weighbridge is a platform for tipping both sideways and rearwards trucks transporting raw materials. Using a 14 x 2.50 meter metal hopper with a load-bearing grate, the raw materials are stored in silos, also with the aid of conveyor belts (capacity of approximately 100 t/h). There are 16 vertical cylindrical metal silos, with volumes ranging from 70 to 1,350 m3. The total storage volume is 5,000 m3. The raw materials pass from the silos via conveyor belts to the upper section of the vertical reinforced concrete structure. It is 17 m high and has a rectangular layout measuring 7.50 m x 6.50 m. In this structure, the finished feed components are first dosed into three containers equipped with controlled weighing systems and monitored by a dedicated central computer that determines the quantities of the various components, based on their percentages, in the finished mix. After batching, the flour is ground using a 92 kW hammer mill with a milling capacity of 15 tons per hour. The flour is then mixed in a horizontal mixer with a production capacity of 30 tons per hour. The resulting mixtures can be bagged or stored loose in silos, or subjected to further dicing or crushing using a dedicated 92 kW steam engine with a production capacity of 7.5 tons per hour of finished product. All the machines in the vertical concrete structure are interconnected by a dust extraction system. Adjacent to the production hall/workshop are two technical rooms (effective dimensions 2.30 x 3.40 m2) which house the boiler. Access to these is independent and directly outside on the opposite side to the central square. In these rooms there is a pressurized combustion boiler with automatic operation using diathermic oil manufactured by IVAR (VR) – model OD-ODV - type ODE C 1000 with the following technical characteristics: nominal capacity = 1,000,000 kcal/hour; furnace capacity = 1,149,500 kcal/hour; pressure = 5 atm; production capacity = 1620 kg/hour. In the second technical room, a silenced rotary compressor branded “Rotar” is installed for the production of compressed air required for the servo controls of the entire system with the following technical characteristics: model = ISC10; V 380 – 3; Hz 50; kW 11; Hp 15; A 23; air delivery-FA.D. 1.40 m3/min; max pressure = 10 bar; 10-liter tank. While the manufacturing company is available to dismantle and relocate the system to any region or continent, our intention is to sell the entire property as-is. We will not be involved in any way with dismantling, which remains the sole responsibility of the buyer. Payment is obviously due in full upfront. Given that thirty years have passed since construction, some components may be damaged, including the 1000-liter compressor unit (which is not included); these must be taken into account. LUMP PRICE €330,000 EX-WORKS SOUTHERN ITALY