Description

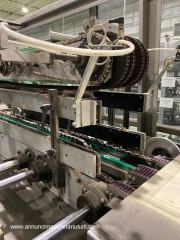

Machine Overview: The ATLANTA COMBIGIOTTO 90-M automatic tray and film packaging machine is designed for secondary packaging of bottles with a 90° side entry. The machine forms a corrugated tray and wraps the product in neutral shrink film, then transports it through a shrink tunnel to obtain stable, retail-ready bundles. Ideal for beverage lines handling PET, glass, or HDPE bottles. Reference No. FA56. Year 2008, overhauled 2022. Condition: Ready for use. Approximate output: up to 25 packs/min, depending on the product and format. Operating concept: Automatic bottle grouping, tray forming/loading, film wrapping, and shrink tunnel consolidation. Packaging configuration: Tray + neutral (shrink) film. 90° infeed allows for compact layouts and easy connection to existing conveyors. Key Technical Data Make/Model: ATLANTA COMBIGIOTTO 90-M Operation Type: Automatic Infeed Orientation: 90° Side Feed Packaging: Tray + Film (Neutral) Tray Magazine/Formation: Available Rated Capacity: Up to 25 packs/min (depending on format and product) Year: 2008 (Revised 2022) Condition: Ready for Use PLC: SIEMENS S7 E 300 Automation & Control PLC-based industrial control with operator HMI for recipe selection, speed setpoints and diagnostics. Inverter-controlled drives for acceleration and smooth product handling. Photoelectric sensors for product presence, jams and film detection. Temperature-controlled shrink tunnel for consistent film performance. Interlocking access doors with safety monitoring for protected zones. Upstream Line Integration: Accepts bottles from conveyor with 90° transfer to infeed section; Integrated sorter/splitter to create package patterns before tray loading. Downstream: Discharge conveyor after the shrink tunnel for connection to inspection, case handling, or palletizing. Signals and handshakes typically include start/stop, fault, emergency stop circuit integration, and speed reference. Mechanical interface and layout drawings available upon request for line engineering. Condition and maintenance: Major overhaul performed in 2022. The machine is ready for use. Preventive maintenance is recommended: periodic checks of the film path, knife/sealing components, tray magazine/former, lubrication, and conveyor wear parts. Performance and versatility: Suitable for a wide range of cylindrical or square bottles commonly used in beverages. Typical packaging patterns for bottles (e.g., 2x2, 3x2, 4x3, etc.) depending on container and tray dimensions. Neutral shrink film for clear presentation; The tray provides rigidity and stacking resistance. Consistent bundle quality thanks to controlled film wrapping and heat-shrinking. Site Requirements: Power supply: 400 V ± 5%, 50 Hz ± 1%, 3P + N + PE (separate neutral and earth). Auxiliaries: 24 V DC. Instrumentation voltages: 24 V AC – 230 V AC. Electrical cabinet protection: IP54; motor protection: IP54. Environmental conditions: Temperature +5°C to +40°C; relative humidity 30%–80% non-condensing; altitude up to 1000 m above sea level; no harmful gases or explosive atmospheres. Compressed air and exact consumption: to be confirmed based on configuration. Machine footprint and utility layout: available upon request. Safety and compliance: Fixed and interlocked guards around moving and hot areas; Emergency stop circuits on accessible sides. IP54 electrical design suitable for typical bottling environments. Safety features include access interlocks, thermal tunnel protection, and fault diagnostics. Install and operate only in non-explosive environments, within the specified environmental limits.